Many years experience spring manufacturer

Navigating the Complexity of Variable Cross-Section in Industry Solutions

2025-01-17

Understanding Variable Cross-Section

Hey there! Let's dive into the fascinating world of variable cross-section, a term that might sound a bit technical, but don't worry; we’ll break it down. In simple terms, a variable cross-section refers to the changing dimensions of an object or material throughout its length. This concept is pivotal across various industries, especially when it comes to optimizing performance and efficiency in manufacturing processes.

Why It Matters

Alright, so why should you care about the variable cross-section? Well, imagine you're designing a bridge or an aircraft wing. Different sections may require distinct properties to handle varying stresses and environmental conditions. By utilizing a variable cross-section, engineers can tailor these structures for maximum strength and sustainability. Quite the game changer, right?

Applications Across Industries

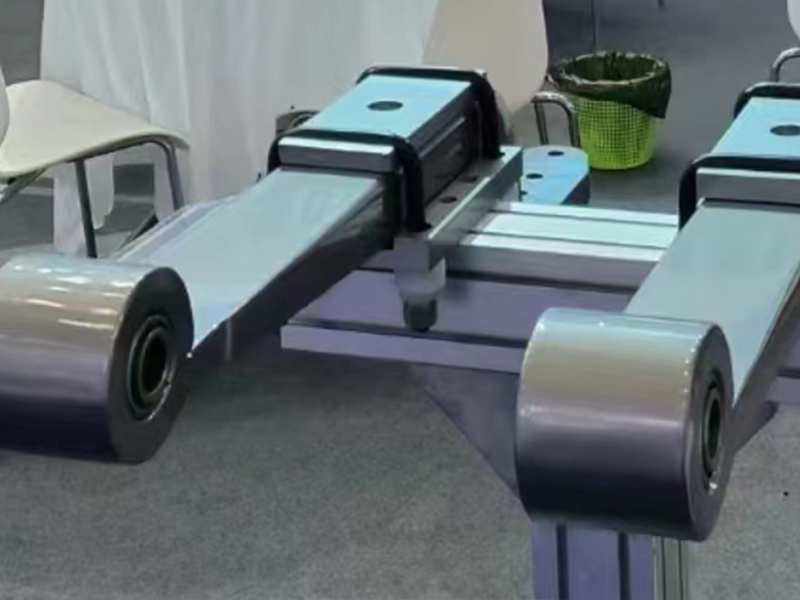

Let’s take a gander at some real-world applications. In the automotive industry, for instance, the chassis of a car might use a variable cross-section to manage weight distribution while ensuring stability. Similarly, in the aerospace sector, wings are often designed with varying cross-sections to optimize aerodynamics and fuel efficiency. It's all about fine-tuning the design to meet specific requirements.

Manufacturing: A Closer Look

Now, let’s zoom in on the manufacturing process. Implementing a variable cross-section can lead to significant cost savings. When manufacturers understand how to manipulate these dimensions, they can reduce material waste, improve strength, and even decrease production time. It’s no wonder that savvy business owners are jumping on this bandwagon!

Challenges in Implementation

Of course, it's not all sunshine and rainbows. Implementing variable cross-section designs can pose its own set of challenges. For starters, accurate modeling is crucial. One tiny miscalculation can lead to major flaws in the final product. Engineers and designers need to be on their A-game, employing the latest software and techniques to ensure precision.

The Role of Technology

Speaking of technology, advancements in computer-aided design (CAD) have made it infinitely easier to create complex variable cross-section shapes. These tools allow for simulations and adjustments in real-time, which is crucial in today’s fast-paced production environments. So, here’s the kicker: the better the tools, the more innovative and effective the designs can be!

Future Trends

As we look to the future, the trend towards sustainability is likely to influence how variable cross-sections are utilized. With growing environmental concerns, industries are increasingly focusing on reducing their carbon footprint. This means designing lighter, more efficient products that can be manufactured with less material. Sounds like a win-win, doesn’t it?

Conclusion: Embracing Change

In conclusion, the concept of variable cross-section is not just a technical jargon; it’s a pivotal element in shaping the future of various industries. From automotive to aerospace, its applications are vast and varied. As technology continues to evolve, we can expect even more innovative uses that could revolutionize how we approach design and manufacturing.

So, whether you're an engineer, a business owner, or just a curious mind, understanding variable cross-section might just give you an edge in the ever-evolving landscape of industry solutions. It’s all about adapting and embracing the changes that come our way!

Key words:

Previous Page:

Contact Us

E-mail:

lfjcbh@126.com

Address:

Dacheng County, Langfang City, Hebei Province